Heatwave Cable Installation

5.3 Heatwave® Cable Installation

Verify the correct Heatwave® Cable has been purchased to heat the area selected and that the correct spacing has been determined for the area being heated, the Watts to be delivered, and the size of system purchased. DO NOT CUT THE RED HEATING CABLE to fit an area. See the Tables in Section 4.2.

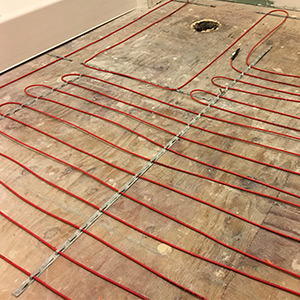

5.3.1 Plan room layout using tape measure, marking pencil, and chalk line. Lay out perimeter of area to be heated first, keeping a minimum of 1.5 inches from walls and or cabinets and the first run of element. Once the layout is complete, roll out the Heatwave® Heating Cable, making sure that both ends of the heating element (where the Heatwave® Heating Cable is pre-connected to the Cold Lead segment) are within 15 vertical and horizontal feet of the power switching thermostat location to accommodate Cold Lead length.

5.3.2 Start by placing the mat such that the connection point and the temperature sensor are in their intended final positions and bring the cold lead to the thermostat or connection box. If a floor alarm or “screamer box” is being used, attach it now (see section 7.4, FLOOR ALARM USAGE). Ensure the connection between the heating cable and cold lead will be properly embedded in thinset and/or mortar.

Continue by laying out Heatwave® Heating Cable on the predetermined layout, and fasten with strapping or plastic clips as described below for the floor surface.

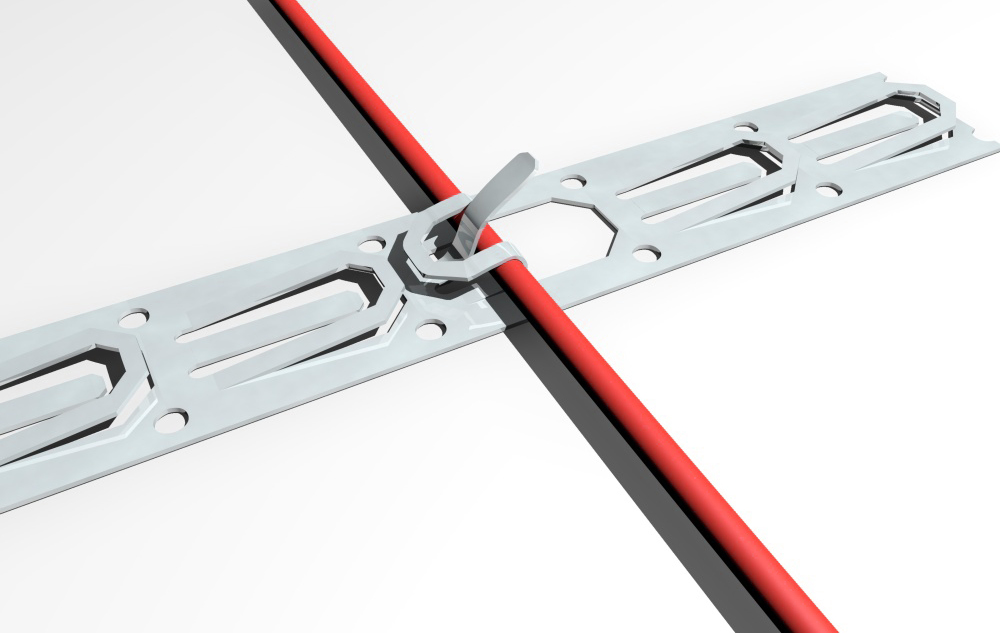

5.3.3 When anchoring the Heatwave® Heating Cable to wood subfloors use either the Plastic Clips (Heatizon Part PLASCLIPKIT) or Heatwave® Cable Strap (Heatizon Part HWCSTRAP33).

Plastic Clips: Each 90 degree bend and each 180 degree turn requires two Heatizon Plastic Clips. Heatizon Plastic Clips should be spaced approximately every 24 inches along the length of the Heating cable. Heatizon Plastic Clips can be inserted around Heatwave® Heating Cable, and secured to sub floor by hammering nail or driving a screw through anchor ends until both plastic tails are flat against sub floor surface. Repeat with each Heatizon Plastic Clip until all clips are secure.

Cable Strap: Heatwave® Cable Strap is used to hold Heatwave® Cables in place on the sub floor surface at the spacing required. Variable spacing options can be maintained using this thin metal strapping. Cut the strap to length using ordinary snips. Anchor the strap with screws on plywood or backer board or with adhesive, hot glue or 2-sided tape on concrete. The strap should be installed on opposite ends of the room and every five feet in between. If additional securing of the cable is required, hot glue or tape can be used to hold in place during the thin set or self-leveling pour. Check continuity between the Heatwave® Heating Cable and the strap as the cable is installed.

5.3.4 If Heatwave® Heating Cable is being installed directly on existing concrete, a Heatwave® Anchoring Plug Kit (HWANCHPLUGKIT) may be purchased. Use a 1/4” cement drill bit to drill holes 1¼” deep in every location where a nail or screw will be located. Install one Anchoring Plug into each pre-drilled hole by tapping plugs until they are flush with the surface of the concrete. Anchoring Plugs should fit tightly in pre-drilled holes. If using Heatizon Plastic Clips, put a clip around Heatwave® Heating Cable and secure by hammering nail through anchor ends directly into the wood plug, until both plastic tails of the clip are flat against the concrete and plug. Repeat with each Heatizon Plastic Clip until all clips

are secure.

5.3.5 Continue laying out and anchoring Heatwave® Heating Cable until complete. Make certain the end of the Cold Leads attached to the Heatwave® Heating Cable return to the thermostat location. When all of the Heatwave® Heating Cable has been installed and secured, run the second Cold Lead (if there are two) parallel to the first Cold Lead back to the thermostat, and secure both Cold Leads to the stud nearest the chosen location for the thermostat. Ensure the connection between the heating cable and cold lead will be properly embedded in thinset and/or mortar. This can be accomplished by routing out a small amount of the floor (create a small channel) to lower the profile of the connection.

5.3.6 MEASURE THE RESISTANCE (TEST #2)

Use a digital Ohm meter to measure the resistance of the Heatwave® Mat/Cable and compare

it to the total Ohms in the tables in Section 4.1 for Mats or in Section 4.2 for Cables. Record

the measured resistance on the Registration Form. Documenting the resistance at each stage

of installation is required for warranty purposes. Also, measure the resistance between each

conductor and the shielding/ground wire. Both should read infinity. Please refer to Section 7

(Commissioning) for instructions on how to measure the resistance.