SnowMeltz® Expanded Layouts

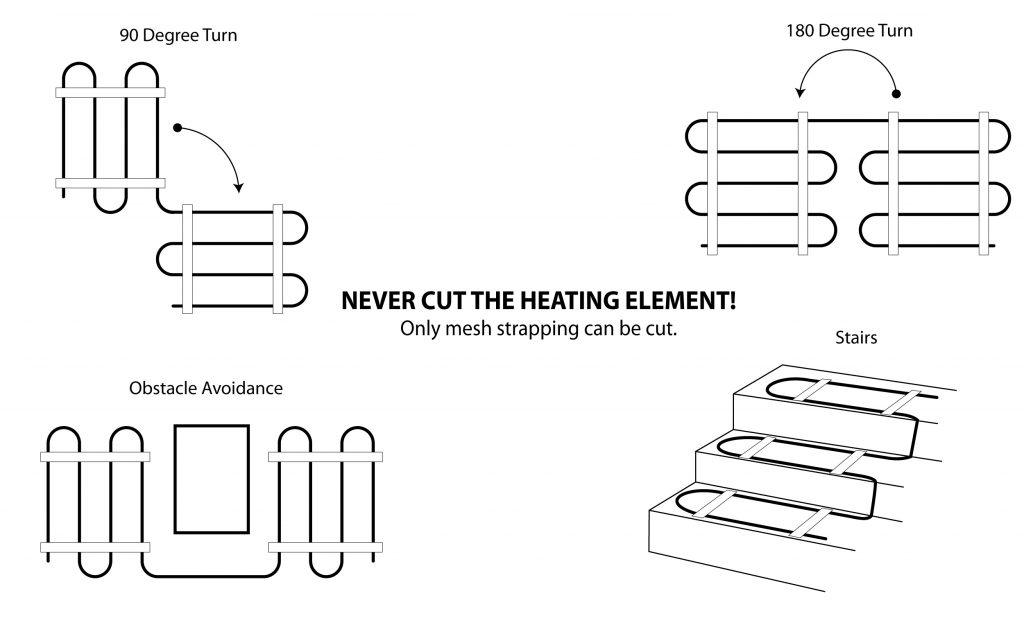

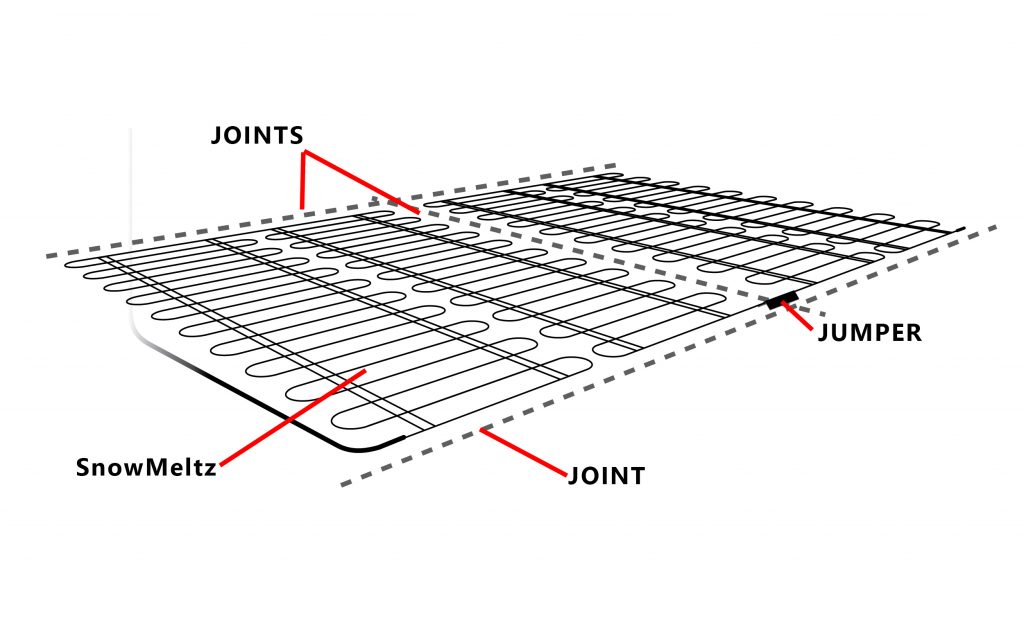

Laying out SnowMeltz using multiple mats follow the following rules:

- SnowMeltz CANNOT overlap any other SnowMeltz cold lead, heating element.

- Maintain at least 3 inch spacing between mats and cold leads.

- Spacing mats greater than 5 inches may cause striping (areas of delayed snow/ice melting).

- Mark all control joint locations before doing layout.

- Find appropriate location(s) for contactor* and/or activator.

- Mark tentative location(s) for junction box(es) and activator.

- Layout mats BEFORE applying the substrate. Do not install them at the same time.

- Plan layouts with any/all joints in mind in order to minimize crossing those joints.

- Follow ALL instructions outlined in the primary SnowMeltz instruction manual for installing SnowMeltz mats.

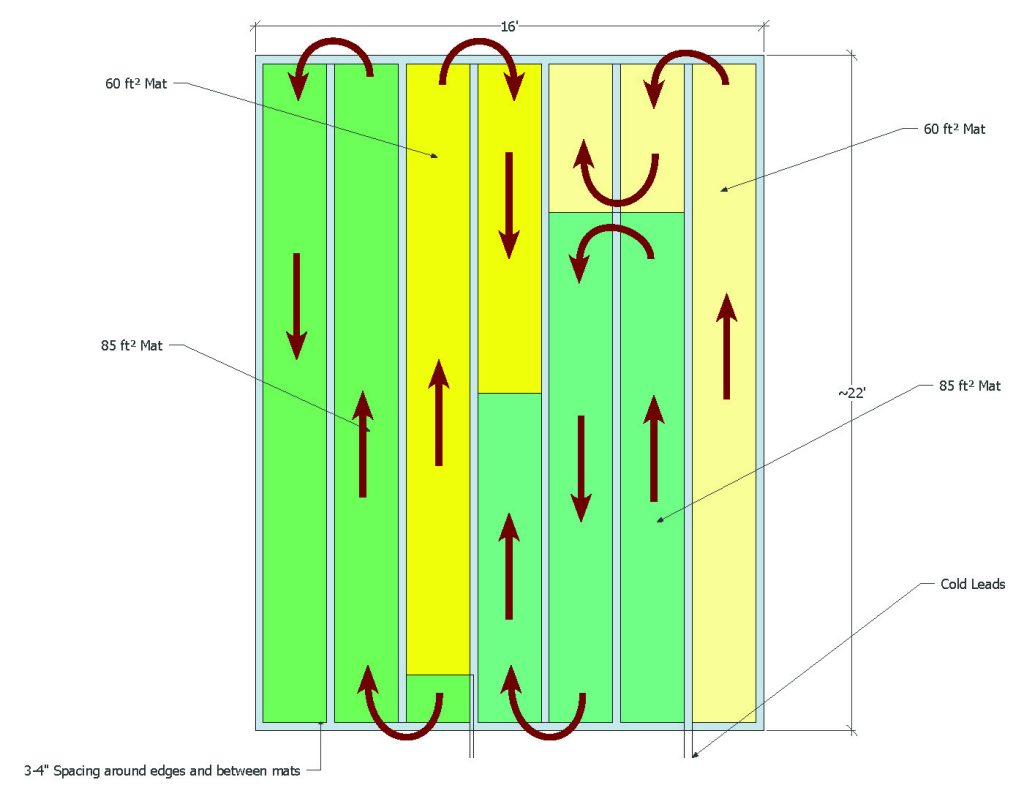

Here are a couple example layouts with the large and jumbo SnowMeltz kits:

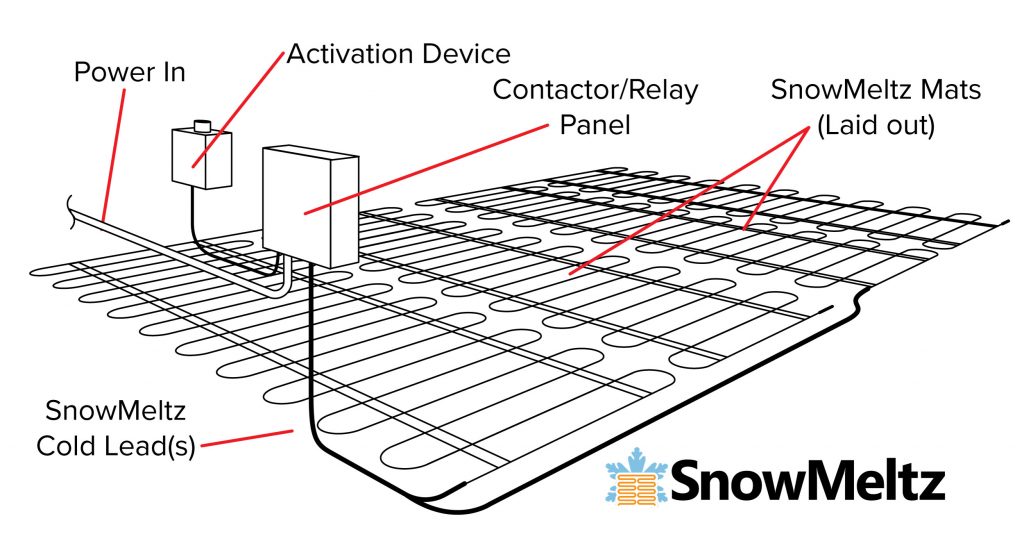

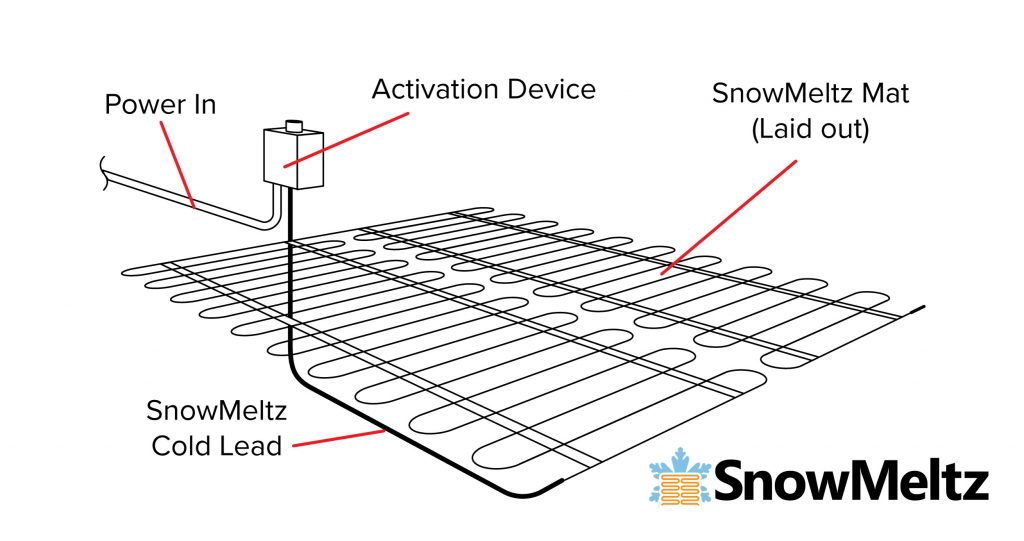

Using the SnowMeltz 290 kit (SM-50W277-37W240-290) to fill a space that is approximately 330 square feet, with 3 inch spacing around the perimeter and between mats. This example has no control joints, therefore no jumpers would be used. All the cold leads would meet the incoming power at the activator device (M326ARS-2Z), where all the electrical connections would be made.

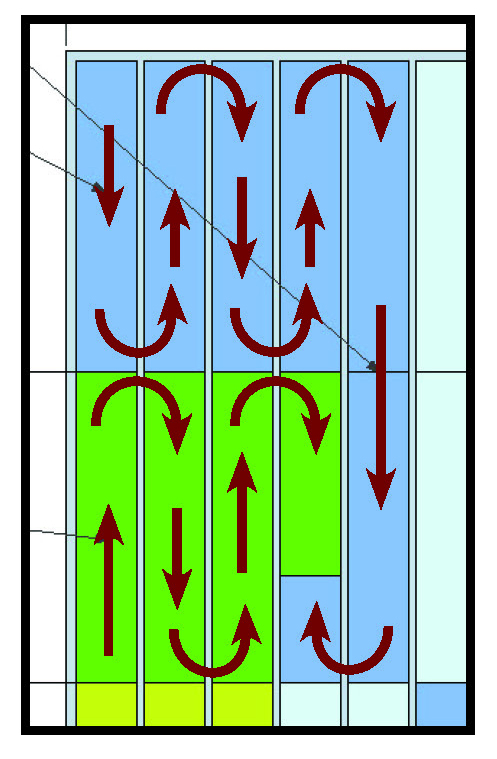

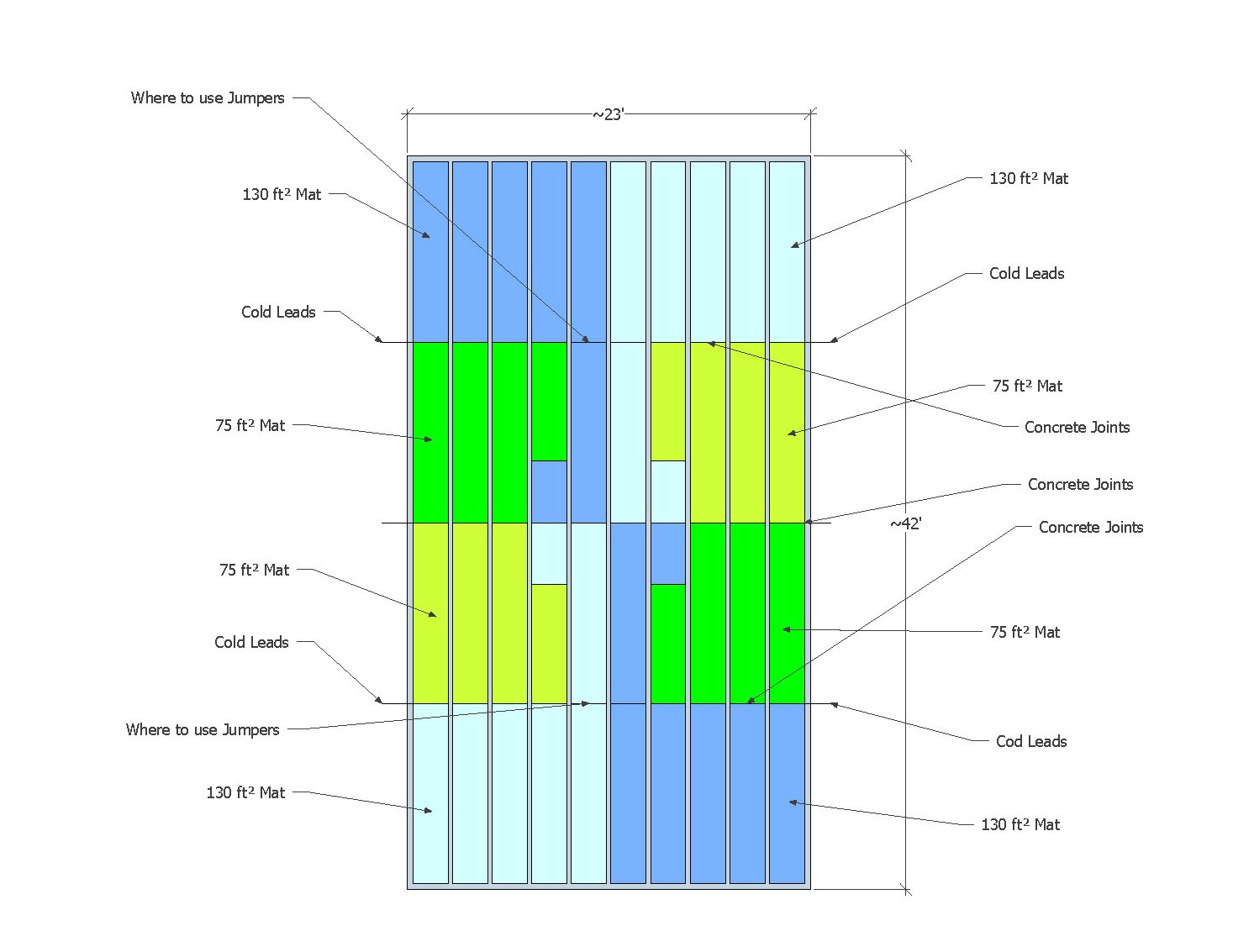

Using the SnowMeltz 820 kit (SM-50W277-37W240-820) to fill a space that is approximately 950 square feet, with 4 inch spacing around the perimeter and between mats. This example has control joints about every 10-11 feet. The mats have been laid out to minimize the number of jumpers required. As you can see, the mats are arranged similarly in four quadrants. See the diagram below for mat routing in each quadrant.

This example would require feeders to each side to junction boxes on either size of the space. These feeder lines should be based on National Electric Code and local codes to carry the appropriate amp load and number of circuits. Any/all junction boxes used should be outdoor-rated.

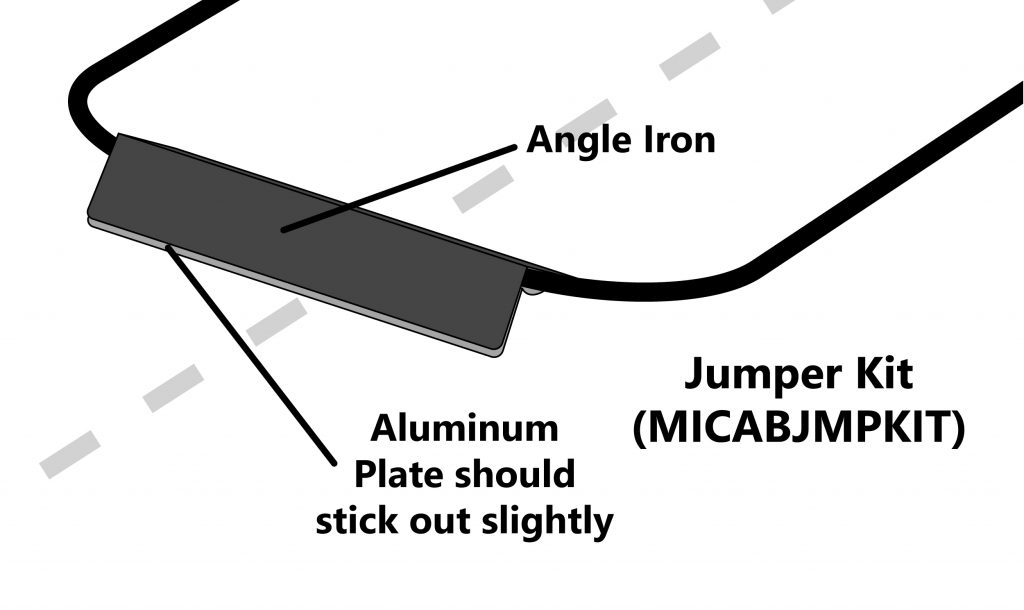

This example uses 1-130 square foot mat and 1-75 square foot mat in each quadrant, with the 130 square foot mat being the one that crosses the horizontal control joint. This is the point where a jumper would be used to protect the SnowMeltz cable from any potential cracking/physical damage. No vertical control joints are needed to be crossed in this example. Be sure to read and follow all installation instructions regarding joints in the primary SnowMeltz manual (SEE: “A Few Concrete Suggestions”).