Product Selection – Complete Kits

Since SnowMeltz CANNOT be shortened, it is vital to choose the correct size system before installing. It is advisable to always get a smaller system for the area, for example: if the area is 48 square feet, choose a 40 or 45 square foot system.

SnowMeltz® Mat Kits – 37 Watts/Ft2 @240VAC

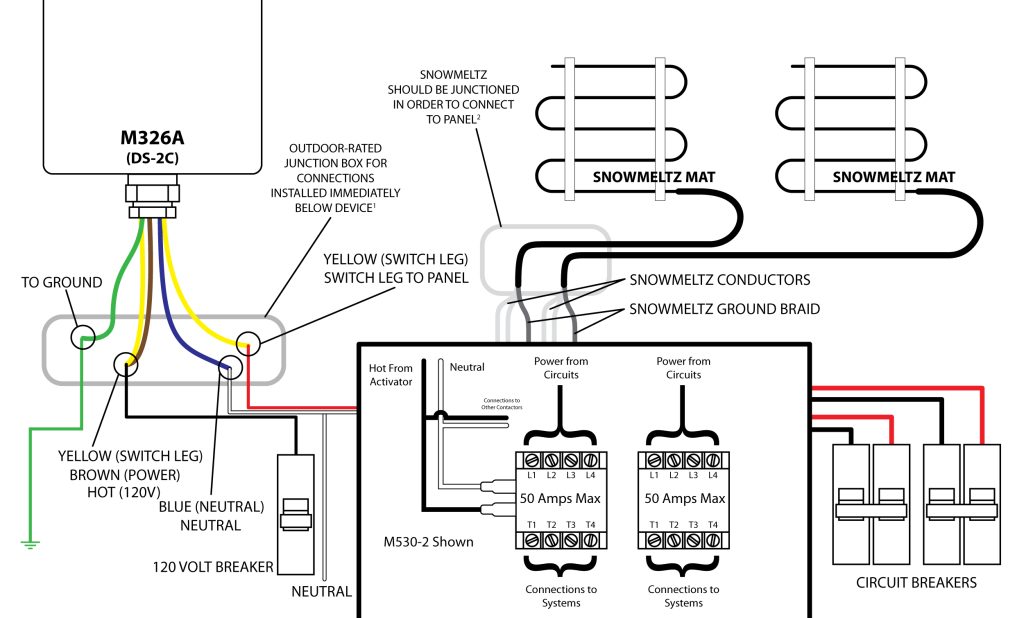

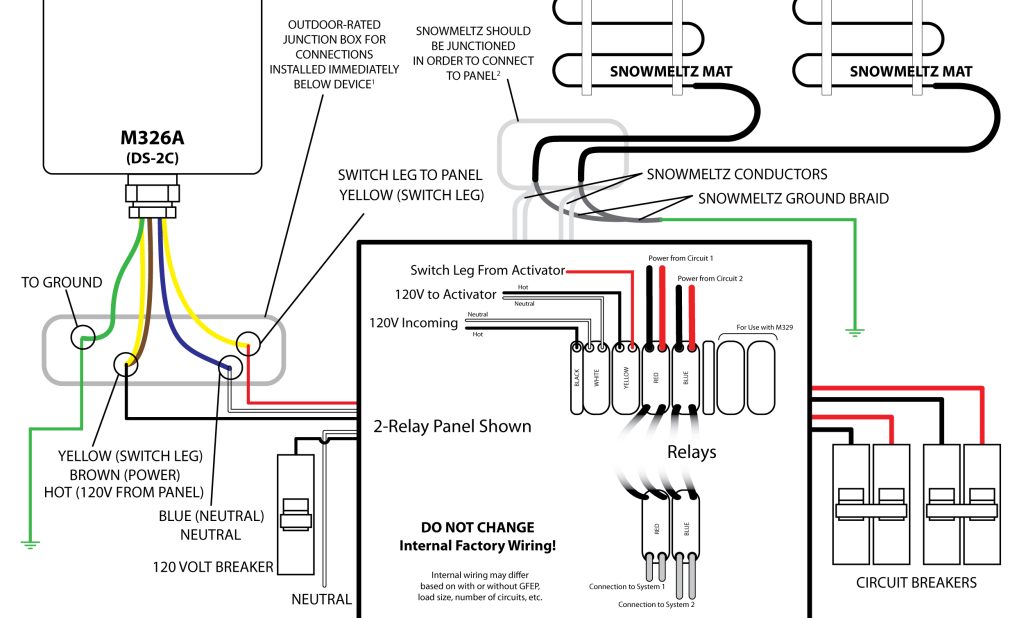

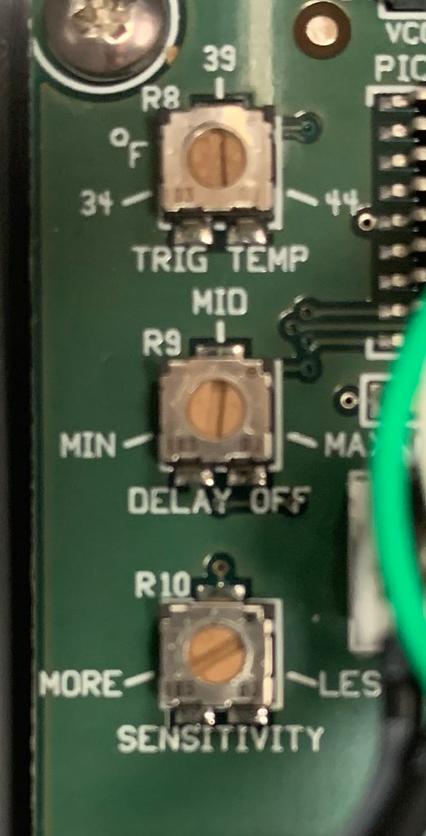

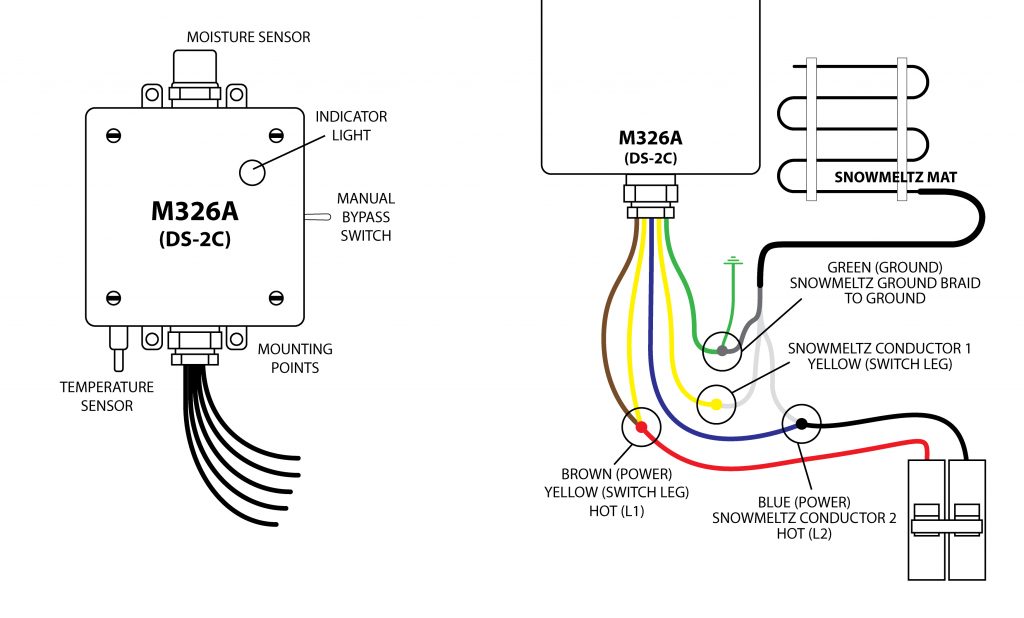

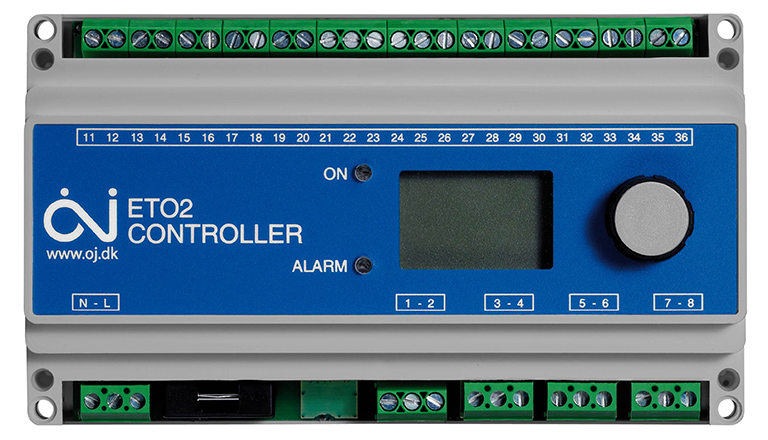

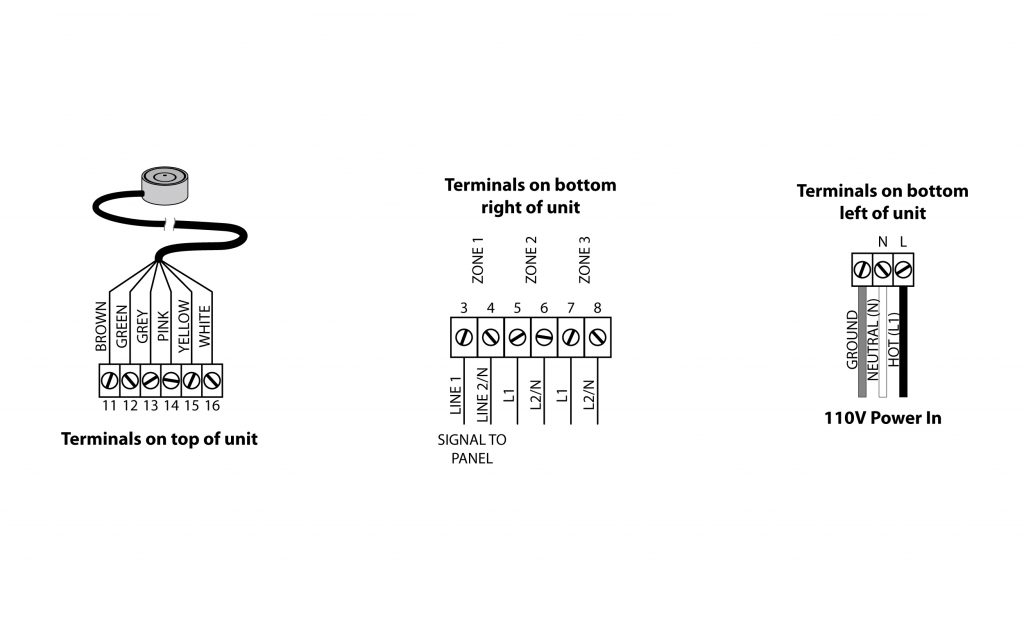

Standard SnowMeltz kits include the SnowMeltz mat(s), an automatic activator, and jumpers. These kits are designed to use a single 20, 30 or 40 amp, 240 volt GFI breaker.

| Heatizon Part Number | Circuit Size | Coverage Area/Square Foot | Mat(s) Dimensions |

|---|---|---|---|

| SM-50W277-37W240-10 | 20 | 10 | 2’x5′ |

| SM-50W277-37W240-15 | 20 | 15 | 2’x8′ |

| SM-50W277-37W240-20 | 20 | 20 | 2’x10′ |

| SM-50W277-37W240-25 | 20 | 25 | 2’x13′ |

| SM-50W277-37W240-35 | 20 | 35 | 2’x17′ |

| SM-50W277-37W240-40 | 20 | 40 | 2’x20′ |

| SM-50W277-37W240-45 | 20 | 45 | 2’x23′ |

| SM-50W277-37W240-50 | 20 | 50 | 2’x25′ |

| SM-50W277-37W240-60 | 20 | 60 | 2’x30′ |

| SM-50W277-37W240-75 | 20 | 75 | 2’x37′ |

| SM-50W277-37W240-85 | 20 | 85 | 2’x43′ |

| SM-50W277-37W240-100 | 20 | 100 | 2’x50′ |

| SM-50W277-37W240-110* | 30 | 110 | 2’x25′; 2’x30′ |

| SM-50W277-37W240-120* | 30 | 120 | 2’x30′; 2’x30′ |

| SM-50W277-37W240-130 | 30 | 130 | 2’x65′ |

| SM-50W277-37W240-135* | 30 | 135 | 2’x30′; 2’x37′ |

| SM-50W277-37W240-145* | 30 | 145 | 2’x30′; 2’x43′ |

| SM-50W277-37W240-150* | 30 | 150 | 2’x37′; 2’x37′ |

| SM-50W277-37W240-160* | 40 | 160 | 2’x37′; 2’x43′ |

| SM-50W277-37W240-170* | 40 | 170 | 2’x43′; 2’x43′ |

| SM-50W277-37W240-185* | 40 | 185 | 2’x43′; 2’x50′ |

* These kits contain two or more SnowMeltz mats to reach the stated square footage.

SnowMeltz® Large Mat Kits – 37 Watts/Ft2 @240VAC

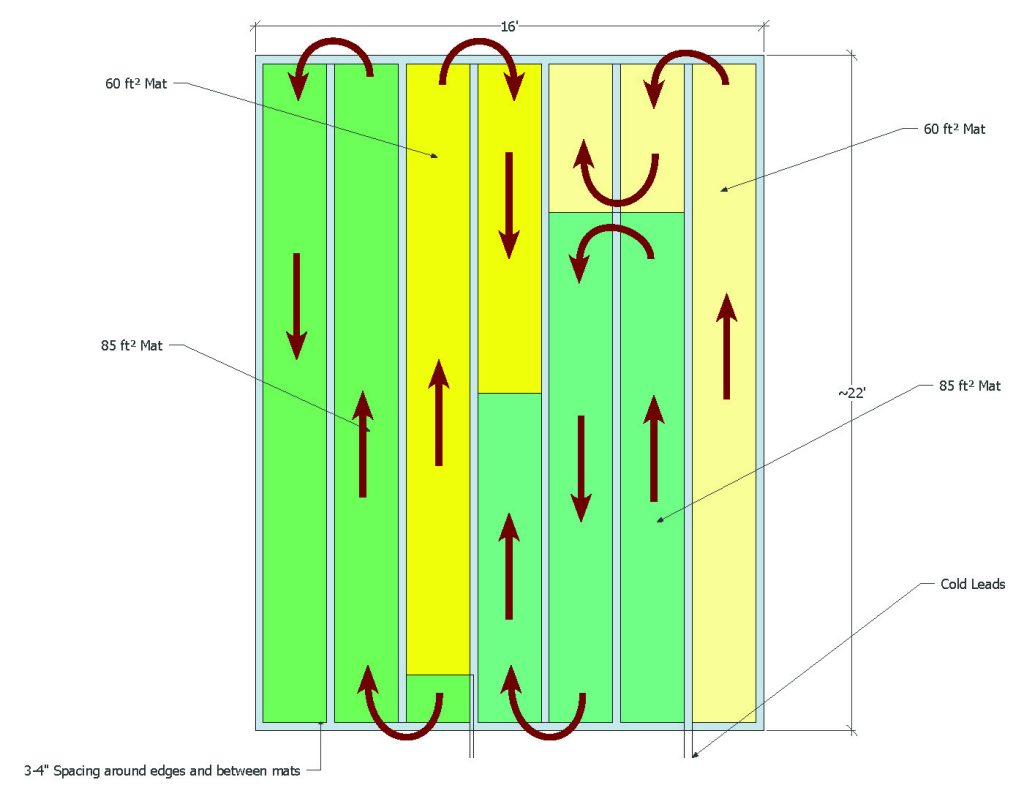

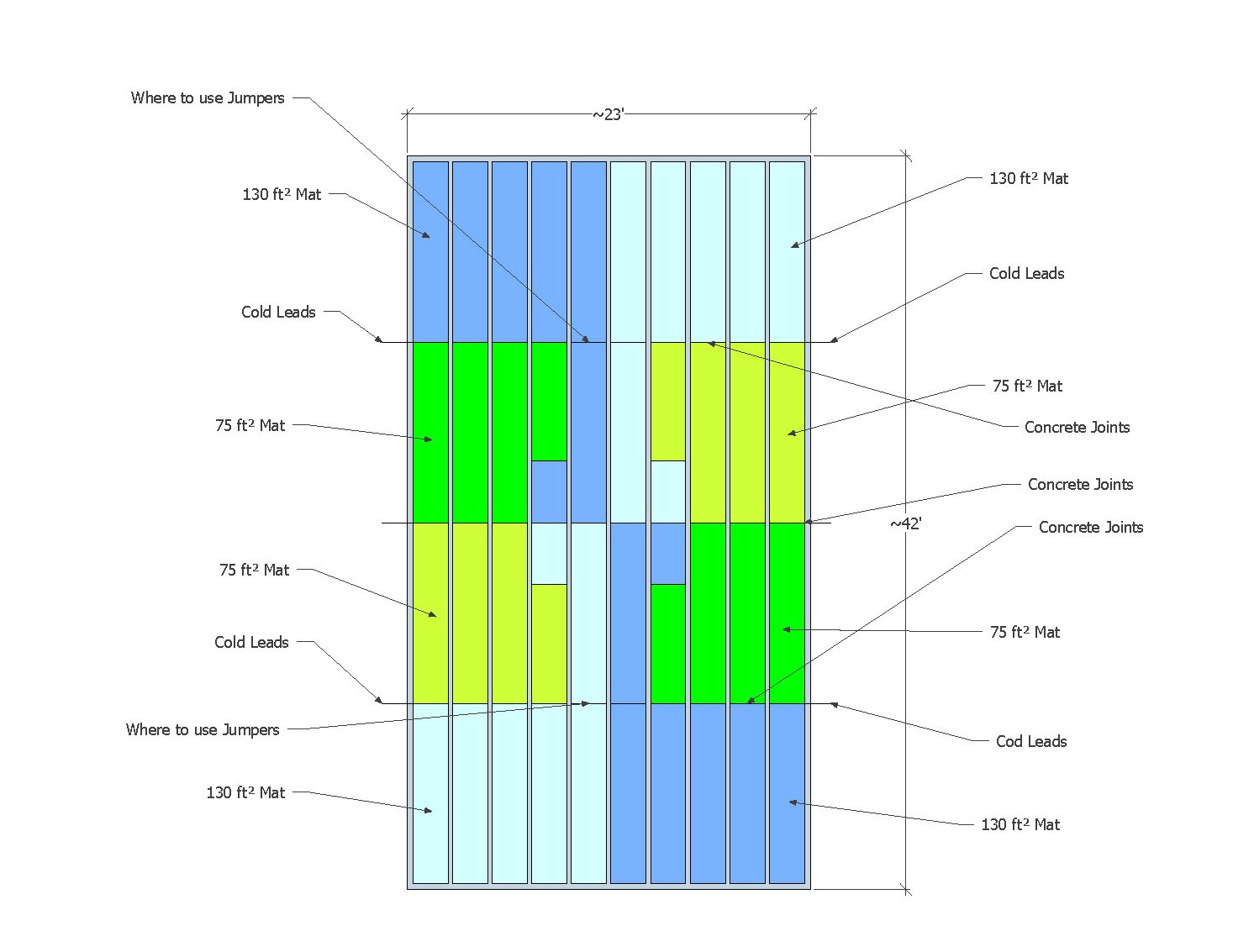

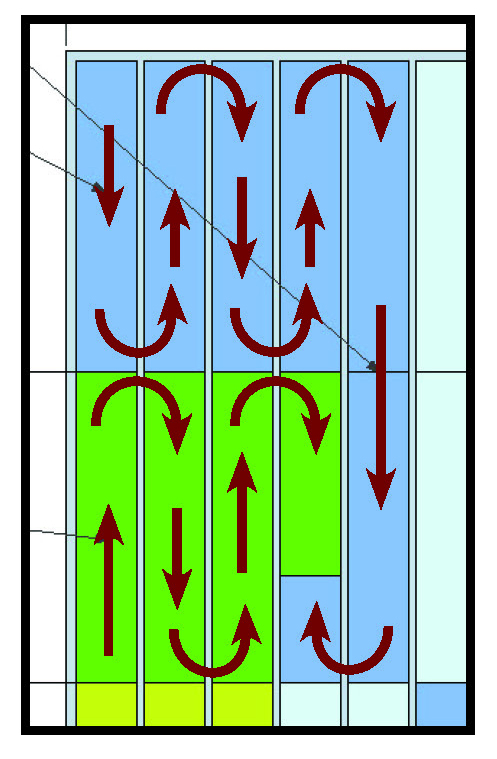

Large SnowMeltz kits include the SnowMeltz mat(s), a dual-circuit automatic activator, and jumpers. These kits are designed to use two 20, 30 or 40 amp, 240 volt GFI breakers.

| Heatizon Part Number | Circuit Size | Coverage Area/Square Foot | Mat(s) Dimensions |

|---|---|---|---|

| SM-50W277-37W240-200 | 2×20 | 200 | (2)-2’x50′ |

| SM-50W277-37W240-220 | 2×30 | 220 | (2)-2’x25′; (2)-2’x30′ |

| SM-50W277-37W240-240 | 2×30 | 240 | (4)-2’x30′ |

| SM-50W277-37W240-270 | 2×30 | 270 | (2)-2’x30′; (2)-2×37′ |

| SM-50W277-37W240-290 | 2×30 | 290 | (2)-2’x30′; (2)-2’x43′ |

| SM-50W277-37W240-300 | 2×30 | 300 | (4)-2’x37′ |

| SM-50W277-37W240-320 | 2×40 | 320 | (2)-2’x37′; (2)-2’x43′ |

| SM-50W277-37W240-340 | 2×40 | 340 | (4)-2’x43′ |

| SM-50W277-37W240-370 | 2×40 | 370 | (2)-2’x43′; (2)-2×50′ |

| SM-50W277-37W240-380 | 2×40 | 380 | (2)-2’x30′; (2)-2×65′ |

SnowMeltz® Jumbo Mat Kits – 37 Watts/Ft2 @240VAC

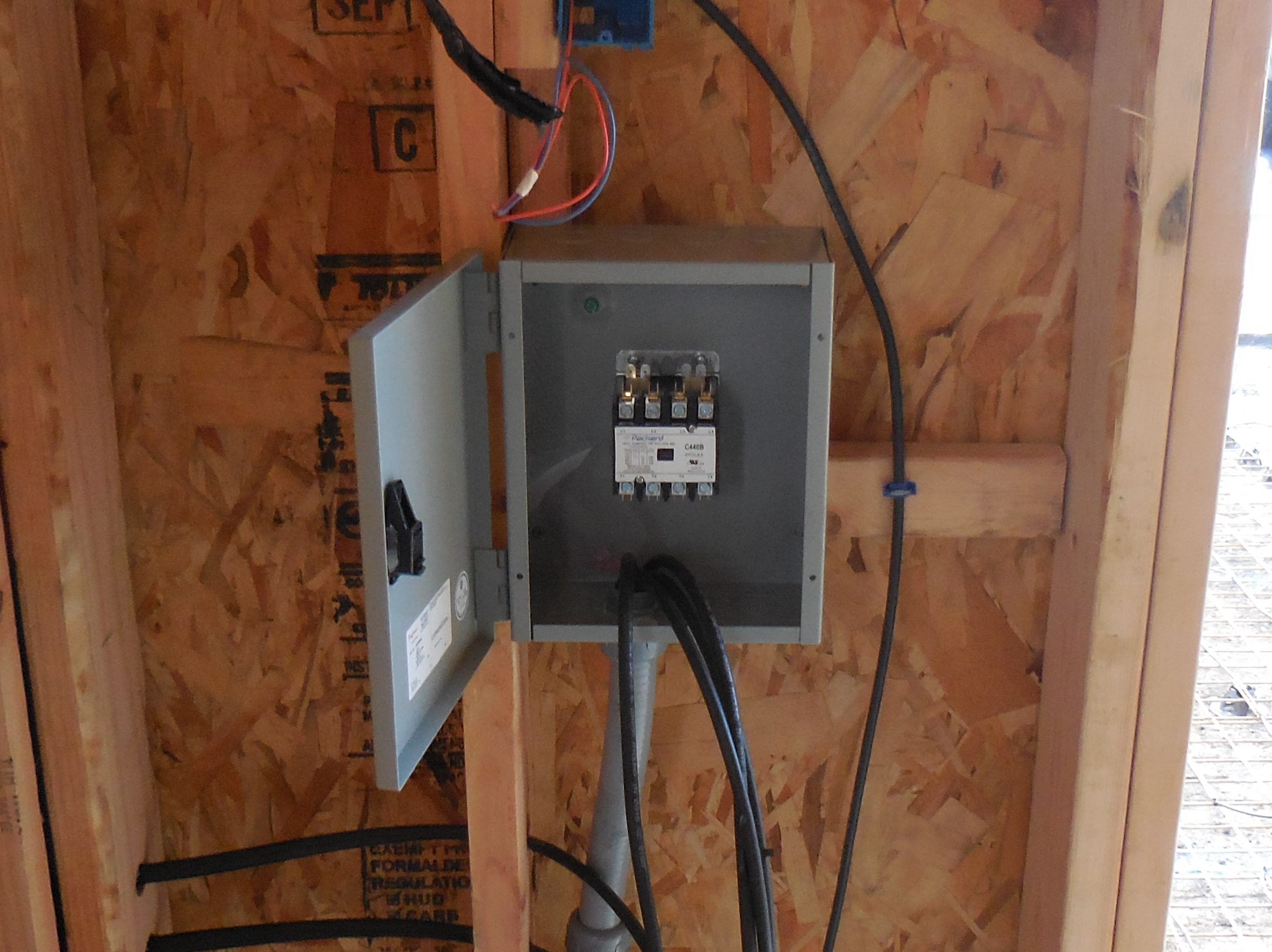

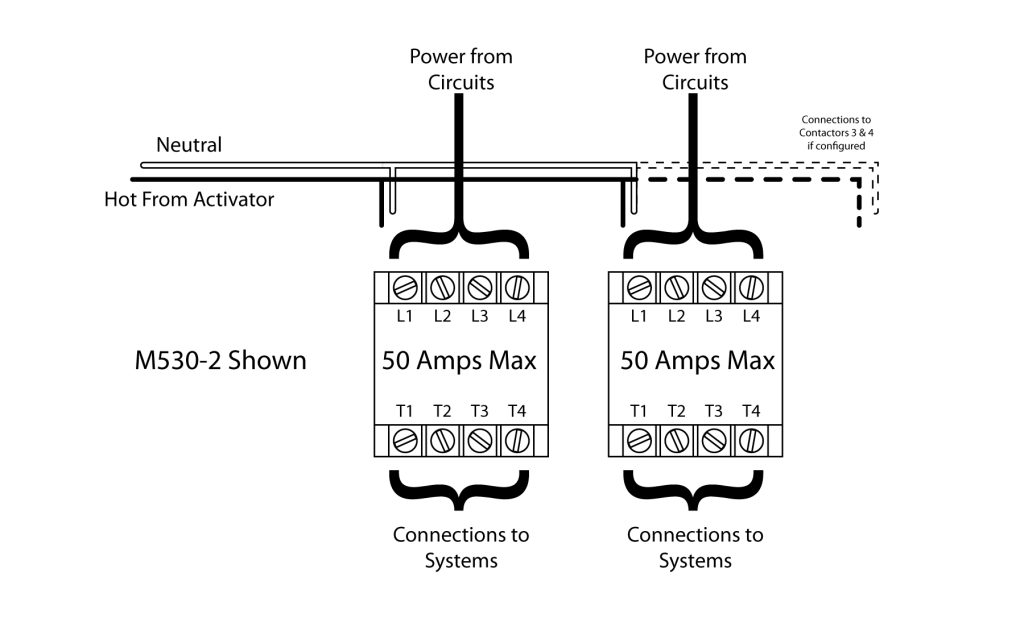

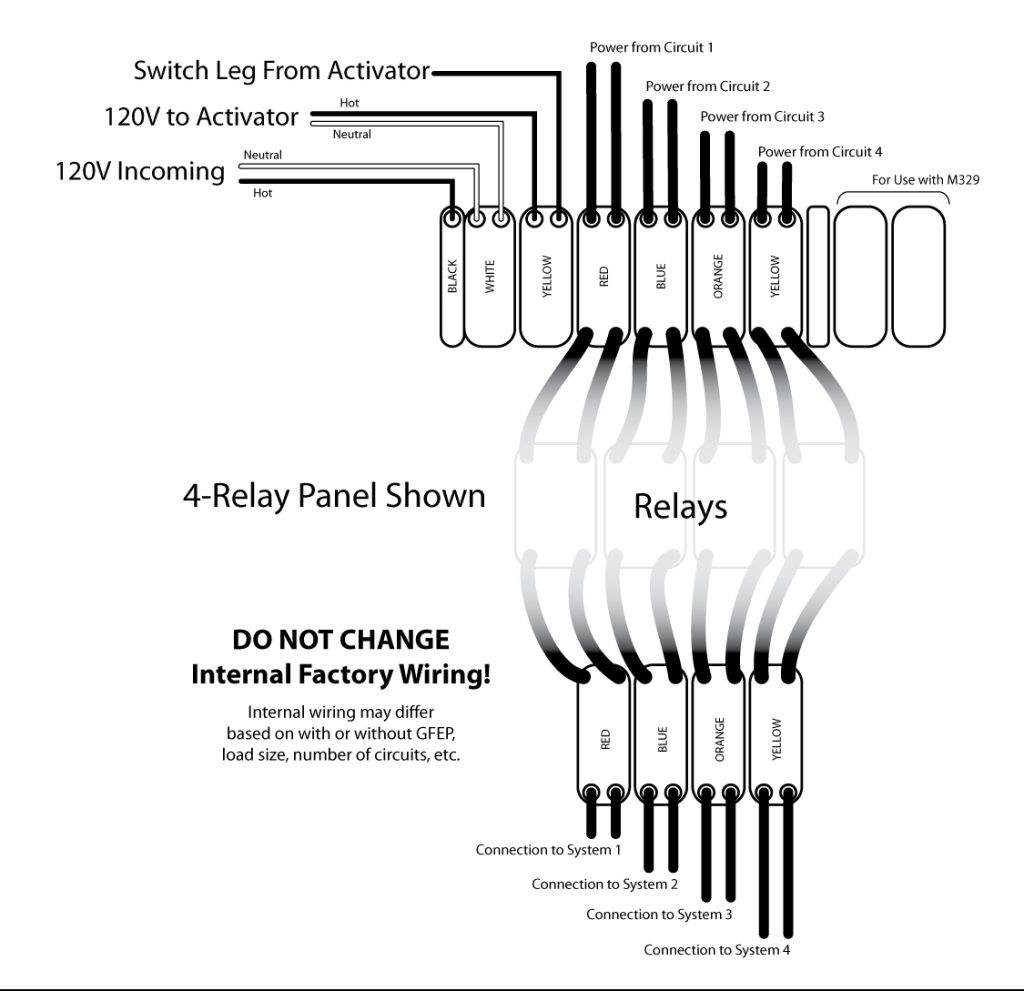

Jumbo SnowMeltz kits include the SnowMeltz mat(s), an automatic activator, contactor panel, and jumpers. These kits are designed to use two, three or four 40/50 amp, 240 volt GFI breakers.

| Heatizon Part Number | Circuit Size | Coverage Area/Square Foot | Mat(s) Dimensions |

|---|---|---|---|

| SM-50W277-37W240-410 | 2×40 | 410 | (2)-2’x37′; (2)-2×65′ |

| SM-50W277-37W240-615 | 3×40 | 615 | (3)-2’x37′; (3)-2×65′ |

| SM-50W277-37W240-820 | 4×40 | 820 | (4)-2’x30′; (4)-2’x65′ |

| SM-50W277-37W240-1040 | 4×50 | 1040 | (8)-2’x30′ |